Whether you’re shopping for brand new alloys or looking to get your wheel refurbished, you will have noticed that diamond cut and powder coated finishes are two of the most popular options. In this article, I’ll be comparing these two types of alloy wheel finishes so you can decide which is the best option for your car.

The Quick Answer

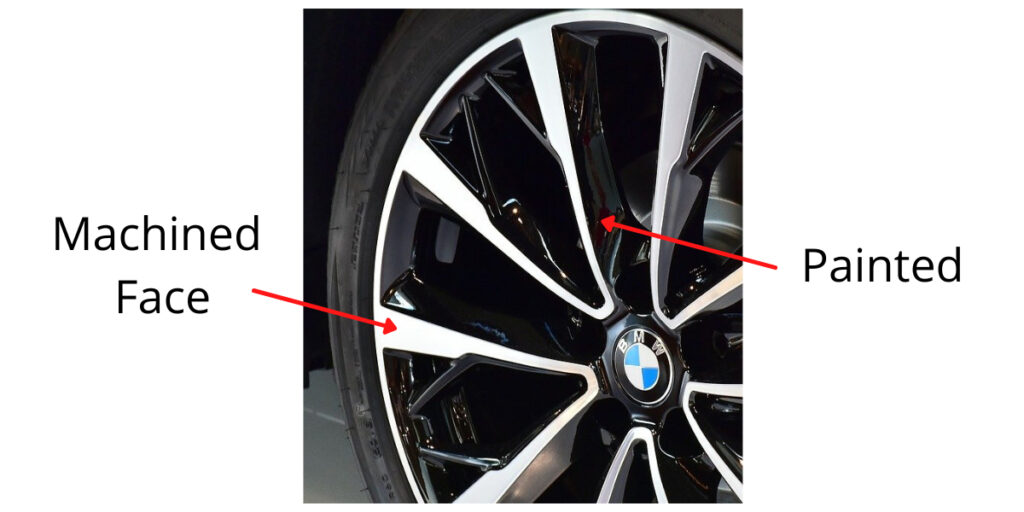

Diamond cut alloy wheels have a two-tone finish due to the machined face, whereas powder coated wheels have a uniform, single colour finish. Powder coated alloys are more durable, cheaper and have a longer warranty than diamond cut alloys wheel are much more susceptible to corrosion.

| Diamond Cut Alloys | Powder Coated Alloys |

| Usually show signs of corrosion within 2 years | Very durable finish which will last many years |

| Two-tone finish (painted and machined) | Single colour finish |

| Available usually in gloss and satin | Available usually in gloss and matte |

| More expensive option | Cheaper option |

| Shorter warranty | Longer warranty |

Diamond Cut Alloy Wheels

Diamond cut alloy wheels are prepared by first painting the wheel and then backing them in an oven to ensure the paint is dry. The wheel is then placed on a a diamond cutting lathe which is computer controlled to machine polish part of the alloy face off. The entire wheel is than lacquered to help protect the finish.

Diamond cut finishes are often used on the highest trim level on most cars such as BWM, Volkswagen Audi and Mercedes, or can be purchased as an upgrade. The main advantage is there appearance. It’s hard to beat the shine on the machined face of a powder coated wheel.

If you have painted alloys and want the diamond cut finish, this can be performed on many types of wheel but it depends on the shape of the face as to whether this is an option.

The issue with diamond cut wheels is that they are prone to corrosion. They can be refurbed but there is a limit to how many times this can be performed without risking the structural integrity of the alloy. They need to cleaned regularly to prevent brake dust build up which is corrosive. Care must also be taken when cleaning to avoid damaging the wheel, hence milder cleaners should be selected.

Check out my complete guide to cleaning diamond cut wheels to learn more.

Powder Coated Alloy Wheels

Powder coated wheels are less commonly seen on new cars. Instead, powder coating is usually performed on older diamond cut or painted wheel finishes.

The process starts by using acid to strip the existing finish and then polishing to ensure the surface is uniform and free from scratches and edges. The wheels are then sandblasted to clean the wheel and roughen the surface so it bonds to the powder coat. The powder is then applied to the wheels and then they are baked in an oven so the powder sets. A clear coat is then applied and the wheels are baked again.

The main advantage is powder coated wheels is their durability as the finish is strong and long-lasting. You can also choose from pretty much every colour possible and even make them glittered. However, sometimes the powder coat finish may have orange peel (a textured finish) particularly if the process has not been performed correctly.

The Differences

Now that we’ve been through a quick overview of each type of alloy wheel finish, let’s take a deeper dive into some comparisons so you can figure out which option is best for you. Here are the factors I’ll be comparing:

- Appearance

- Durability

- Price

- Repair Process

- Warranty

Appearance

Diamond coated wheels can be painted any colour, but they will always be easily identified by the machined face. I personally think this is a really nice finish as the face is incredibly shiny, however it’s all personal preference and some car owners might not be a fan. You can get matte paint, but usually it’ll be a gloss or sometimes a satin finish on the rest of the alloy.

Powder coated wheels come in a huge range of colour choices but are often limited to either a gloss or satin finish. You can get some unique looks using powder coating using glittered powder.

The main difference is that diamond cut wheels will usually have a two or three-colour finish (the paint and the machined face), whereas powder coated wheels will usually be one uniform colour, although you can get a two-tone finish with additional steps.

Durability

The main advantage that powder coated alloys have over diamond cut alloys is that the powder coated finish is far more durable. Powder coating is the most durable finish available and will protect the wheel more against corrosion. Diamond cut finishes on the other hand are very sensitive and susceptible to corrosion.

Diamond cut wheels can become corroded when the lacquer is damaged and this occurs quite easily, for example due to a stone chip which is impossible to avoid. Once the lacquer is slightly compromised, water will go underneath it and give it a milky appearance and ruin the shiny machined face.

No matter how careful you are, this corrosion is still likely to happen. Ceramic coating the wheels will help to an extent but they will not remove the risk. When speaking to an alloy wheel salesperson about the corrosion issue, they said that most diamond cut finishes only last between 1-2 years before the corrosion sets in. This can be even sooner if the car is driven frequently on high speed roads as this increases the chance of stone chips.

Warranty

Since diamond cut wheels may only last a year or so before corrosion, your luck is in if you’ve got a brand new car. Unless the wheels have been kerbed, you can usually get them replaced under your manufacturers warranty. However, if you purchase aftermarket diamond cut wheels, then they’ll usually only have a 1 year warranty. Painted finishes often have a 2 year warranty which reflects how the manufacturers feel about the durability of this finish type.

Powder coated wheels come with a longer warranty than diamond cut wheels but it really depends on who does the process. Some companies actually offer a lifetime warranty on this type of finish.

Repair Process

Diamond cut and powder coated wheels can both be repaired if the wheels are curbed. Powder coated wheels are rarely refurbed due to corrosion issues, but this is of course a lot more common with diamond cut wheels.

Unfortunately, there is a limit to how many times a diamond cut alloy can be re-machined, as the process essentially removes a proportion of the front of the wheel. This can only be performed a limited amount of times to ensure that the structural integrity of the wheel is not compromised.

Price

In the USA, diamond cut alloy wheel finishes start at around $120 per wheel whereas powder coated finishes start at around $100 per wheel. In the UK, diamond cut alloy wheel finishes start at a roughly £75 per wheel and powder coated finishes start at approximately £55.

| Requirement | Diamond Cut Finish | Powder Coat Finish |

| 4 alloys 13-17” | $475 | $400 |

| 4 alloys 18-19” | $500 | $425 |

| 4 alloys 20-21” | $525 | $450 |

| 4 alloys 22” | $550 | $475 |

| Requirement | Diamond Cut Finish | Powder Coat Finish |

| 4 alloys 13-17” | £275 | £225 |

| 4 alloys 18-19” | £300 | £250 |

| 4 alloys 20-21” | £325 | £275 |

| 4 alloys 22” | £350 | £300 |

Which Should You Choose?

If you are looking for the most durable finish, then powder coated wheels are by far the best option compared to diamond cut wheels. However, it also depends on the look you’re going for. If you have your heart set on the appearance of diamond cut wheels just be prepared to refurbed them when you notice corrosion.

Check out my article on 3 durable alternatives to diamond cut wheels to consider more of the finish options on offer.

Here are some more articles you might find useful: