There are three main types of machine polishers used for car detailing:

- Random orbital

- Forced rotation

- Rotary

The main difference between rotary polishers and the other two types, is that rotaries only spin in one direction. Random-orbital and forced-rotation machine polishers are actually both classified as “dual-action” polishers because they spin in two directions. Here’s a link to an article comparing dual-action and rotary polishers.

What is a Dual-Action Polisher?

Dual-action polishers spin in two directions. There are two types of dual-action polisher:

- Random orbital

- Forced rotation (also known as gear-driven)

There is a little confusion here because “dual-action” and “random orbital” are often used interchangeably, but it is more correct to say that a random orbital polisher is a type of dual-action polisher.

Again, there is some confusion with forced rotation polishers often being described as a completely separate type of machine polisher to a dual-action. However, again, it is instead correct to say that a forced rotation polisher is just a type of dual-action polisher.

In this article, I’ll be explaining in-depth the difference between the other two types of machine polisher: forced rotation (gear-driven), and random-orbital polishers.

How Do They Work?

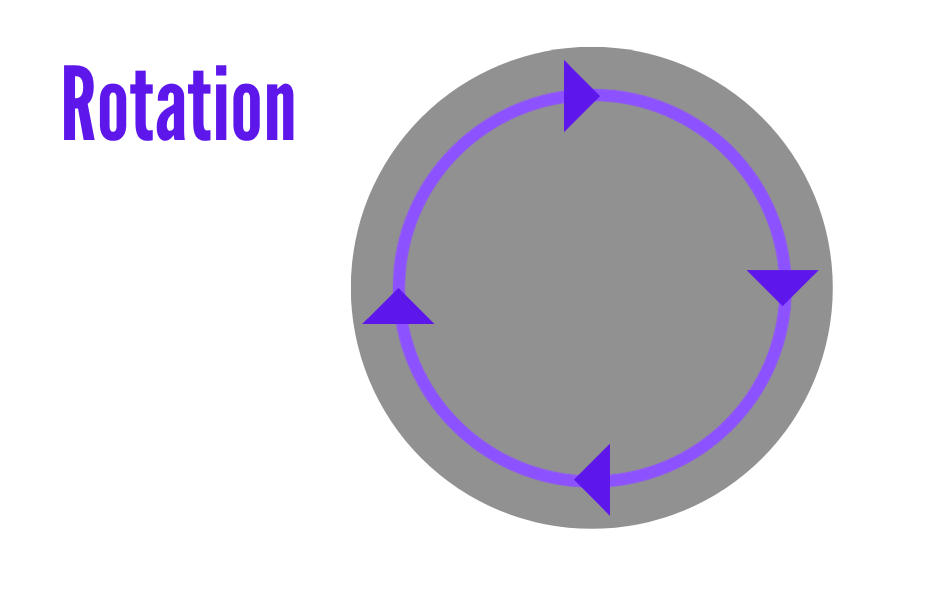

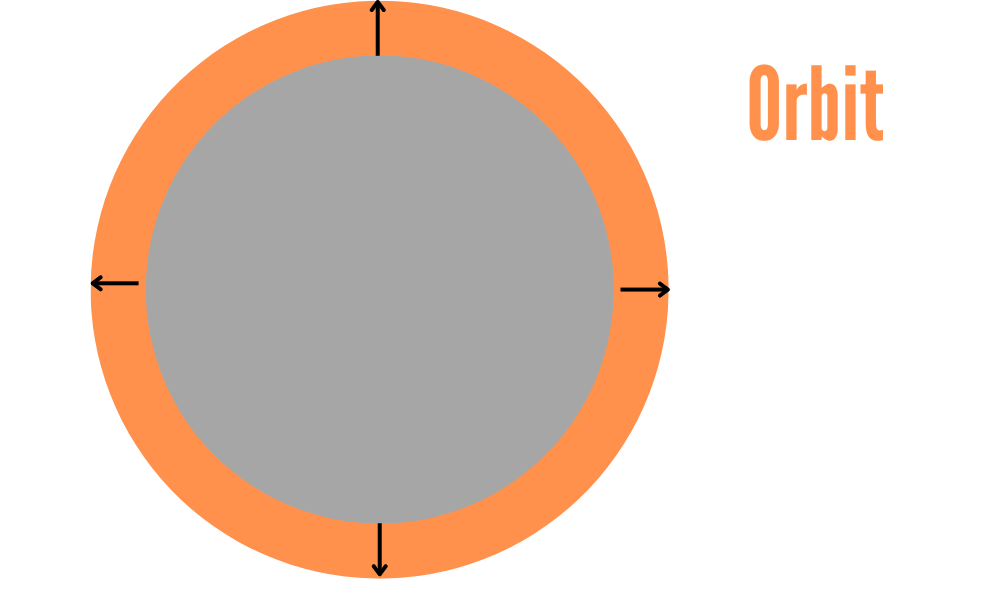

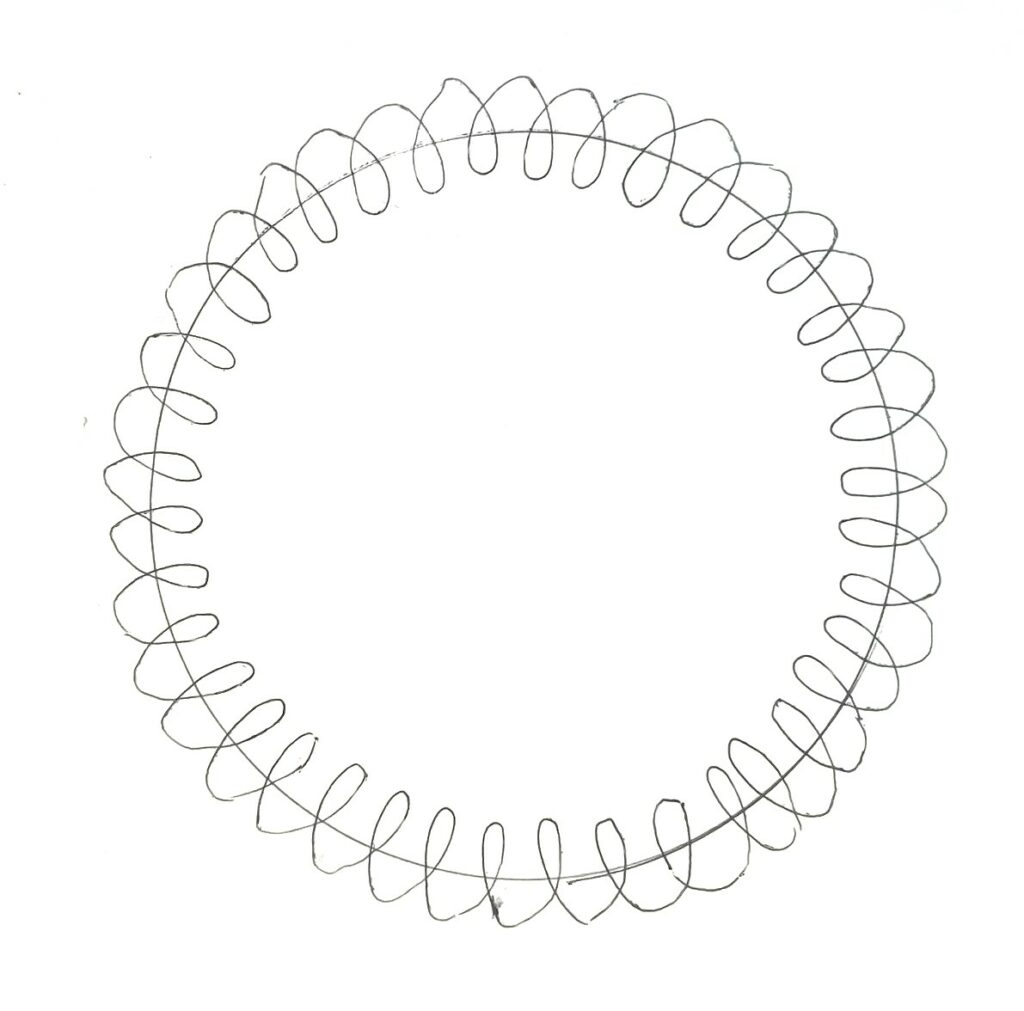

As I mentioned in the previous section, both these types of machine polishers move the pad in two directions, these being the rotation, and the orbit.

With a forced-rotation machine polisher, the rotation and orbit are tied together. This means that you get the same movement direction and speed every time regardless of the pressure you are putting down, and the angle of the polisher.

With a random-orbital machine polisher, the rotation part of the movement is random. Since the rotation is not “forced”, the speed can vary depending on the angle and how much pressure you are putting down. This means the random-orbital polisher can stall if you put too much weight down and don’t keep the pad flat.

This not only affects how the machines feel, but also how the pad moves. Here’s a diagram of the pad movement you get with a forced-rotation and random-orbital DA polisher.

How Can You Tell Which is Which?

If you take a random orbital polisher and try to rotate the pad with your hand (when it’s turned off!), it will be “free-spinning”, whereas with a forced-rotation polisher there will be resistance as you will have to move the gears manually.

Which Has the Most Cut?

Both the random-orbital and forced-rotation machine polishers have an excellent level of cut and are capable of removing 1500 grit-sandpaper marks from the paintwork when using the correct pad and compounding polish. It is possible to achieve the same level of cut with either machine.

However, I want to provide a bit more information on this topic.

Forced-rotation machines do not stall-out, and both the rotation and orbital movements of the pad will happen regardless of the shape of the panel and the technique. This gives it a great level of cut on all panels.

With a random-orbital polisher, it can stall out if the pad isn’t flat and too much pressure is being put down. This means that the average user will get less cut (due to the machine not constantly rotating). If however, you have perfect technique though, this will not be the case.

Which is Best at Finishing?

Here we’re talking about the ability of these machines to produce a hologram and swirl-free finish with maximum gloss.

In general, it is easier to get a better high-gloss finish using a random orbital DA compared to using a forced-rotation polisher.

Every time you polish the paintwork, you will leave some mark behind on the finish i.e. it will not be completely flat.

Random-orbital polishers leave a less visible mark is because they have a constantly changing pad movement, making it easier to refine the finish and less likely to leave visible marks on the surface from the pad.

Forced-rotation machine polishers are still very capable of producing an excellent finish, however it is typically a bit tougher when working on softer paintworks. This is because the pad rotation is more uniform.

Which is Best for Edges and Curves?

Most vehicles have tight corners, curved panels and of course all of them have edges on each panel.

There are two differences here:

- Random-orbital polishers are safer on edges and less likely to “burn through”

- Forced-rotation polishers are more efficient on curves and contours

This again comes back to forced-rotation polishers always keeping the pad moving, and random-orbital polishers having the potential to stall if tilted on an angle.

With a random-orbital polisher you have less potential to burn through on an edge because the pad is likely to stall if you put too much pressure on a corner. However, since the movement is more random and has a greater offset, it’s less efficient because you aren’t always reaching the edge of the panel with the pad.

Hence, with a random-orbital polisher it is best to use a smaller pad on the edges and contours to ensure you are working on that area with more focus and less risk of stalling.

With a forced-rotation polisher it is easier to get all the way to the edge on a panel without the pad stalling, and hence keeps the process efficient without having to swap to a smaller pad. The same goes for curved and contoured panels.

How Many Machines are Needed?

Leading on from the previous section, in order to achieve a good result and work efficiently on all areas of the car including curved panels and contours, you will need to use different sized-pads with a random-orbital polisher. This will prevent the machine stalling out.

The problem here is though, that random-orbital polishers are typically designed to only work with one size of pad as they have a counter-weight in them to ensure the machine stays balanced.

This means that you may need to have a random-orbital polisher with a 5″ backing plate, another with a 3″ backing plate and even one with a 1-2″ backing plate in order to work on all areas of the car effectiveness. Hence, you’ll need three separate machines which can get really expensive.

Since forced-rotation machines won’t stall out, you don’t need to down-size to a 3″ plate on certain sections and can continue with the 5″ plate. It can still be useful to get a nano-polisher (1″-2″ plate) though for very tight areas.

Which Type of Machine is the Safest?

Both the forced-rotation and random-orbital machine polishers are “safer” than rotary machine polishers as they are less likely to burn-through on edges etc.

When comparing these two types of dual-action polisher, the random-orbital polisher is safer than the forced-rotation. This is because the pad on a random-orbital will stall out if you put too much pressure on a certain area, so it almost acts as a built-in safety feature.

You also usually get less heat-build up with a random-orbital polisher.

Which is Easier to Use?

A random-orbital dual-action machine polisher is typically considered easier to use compared to a forced-rotation polisher. This is because it’s considered a slightly “safer” machine.

Forced-rotation machine polishers are a little trickier and harder to keep control of, because both the orbit and rotation are “forced” so it can feel like you’re fighting with it a bit if you don’t have much experience.

There is some argument that the forced-rotation machine is actually easier to use though, as you don’t have to worry about the pad stalling out.

In conclusion, both machines can be mastered and although there’s some learning curve, you can get great results relatively easily with both types.

Summarising the Differences

| Random Orbital | Forced Rotation |

| Only the orbit of the machine is forced | Both the orbit and rotation are forced |

| The pad will stall if too much pressure is put down | The pad will continue to spin regardless of the pressure |

| Easier to achieve a high-gloss finish on softer paint | More efficient on curved panels and edges |

| You need to down-size the pad to polish contours | You can keep the same pad size on contoured panels |

Which Type of Machine Polisher is the Most Popular?

I actually asked this question on my Instagram page @autocarehq as I wondered which the most popular type of machine polisher would be, and here were the results:

This poll received a total of 246 votes.

Examples of Each Type of Machine

Random-orbital machine polishers:

- Rupes Big Foot LHR15

- Flex XFE Random Orbital

- Maxshine M15 Pro

Forced-rotation machine polishers:

- Flex XCE Forced Rotation

- Rupes Bigfoot Mille

- Vertool Forced Drive